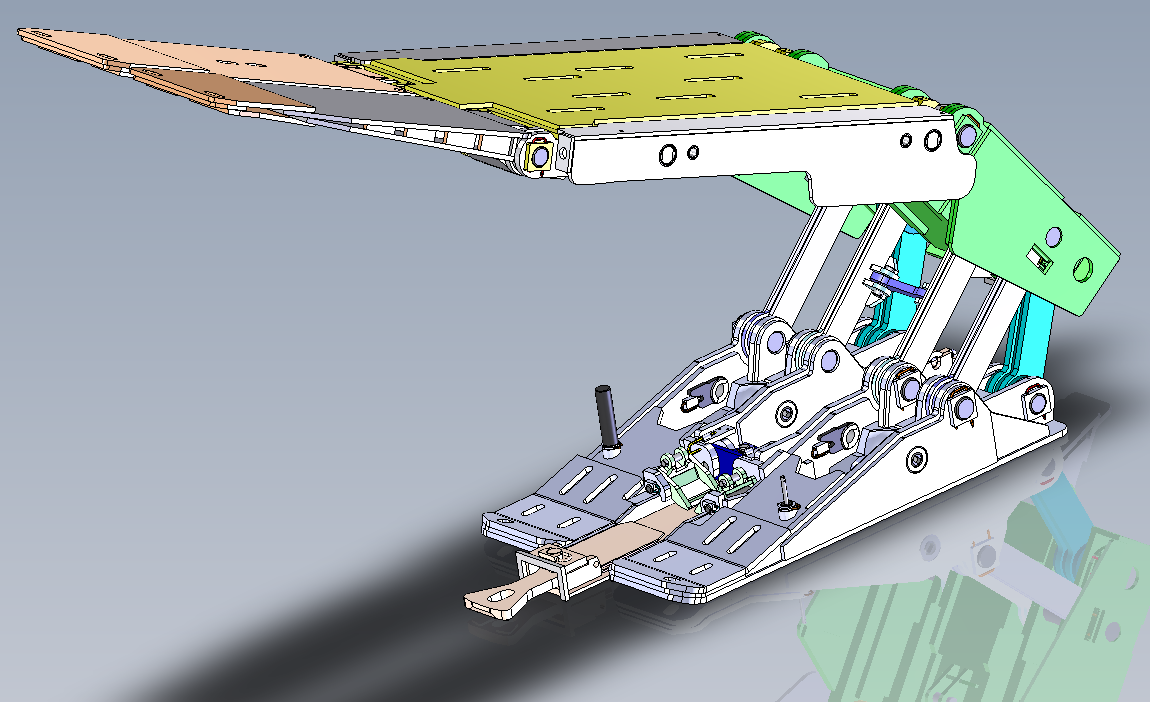

Powered supports

Powered supports are designed to provide working space in longwall when mining in low, medium and powerful formations. They are designed to support the roof over the longwall working space.

When designing a powered support, attention is paid, above all, on the safety of the operating personnel, as well as to the difficult mining and geological conditions. The support is designed taking into account the operational period of more than 15 years, assuming continuous operation.

The main components of the fasteners are the following: base, hydraulic props, cappings, guard rail, traction mechanism, auxiliary device for advancing ram and other power hydraulics, as well as the control hydraulic system.

| № | Parameters/Section | 1KD90 | 2KD90 | 3KD90 | 2KD90Т | 3KD90Т | 4KD90Т | DМ | KPHS |

| 1 | Specific resistance on 1m² of supported area, kN/m² | 430 | 500 | 550 | 743 | 800 | 820 | 370-505 | 830 |

| 2 | Section resistance, kN, no more than | 2800* | 3000* | 3200* | 4800* | 4800* | 7580* | 2100-2300 | 1250 |

| 3 | Hydraulic extension coefficient, no more than | 2 | 2 | 2 | 1,95 | 2,45 | 2 | 2,4 | 1,94 |

| 4 | Coefficient of initial spread, no more than | 0,8 | 0,8 | 0,8 | 0,7 | 0,7 | 0,7 | 0,8 | 0,8 |

| 5 | Maximum pressure in the pressure line, MPa | ||||||||

| * maximal | 32 | 32 | 32 | 32 | 32 | 32 | 32 | 32 | |

| * minimal | 20 | 20 | 20 | 20 | 20 | 20 | 20 | 20 | |

| 6 | Support during moving of the section, kN/m², no more than | 10 | 10 | 10 | 15 | 15 | 15 | 15 | 15 |

| 7 | Moving force (at maximum operating pressure in the pressure line) kN, | ||||||||

| * of the section | 304 | 392 | 392 | 392 | 490 | 492 | 300 | 112 | |

| * of the conveyer | 180 | 232 | 232 | 230 | 290 | 288 | 180 | 202 | |

| 8 | Average roof pressure, MPa, no more than | 1,5 | 1,5 | 1,5 | 1,8 | 2 | 2,6 | ||

| 9 | Support section height, mm | ||||||||

| * minimal | 640(+20) | 710(+20) | 1000(+20) | 750(+20) | 1730(+20) | 1750(+20) | 460(+20) | ||

| * maximal | 1345(+20) | 1440(+20) | 2030(+20) | 1470(+20) | 3400(+20) | 3500(+20) | 810(+20) | ||

| 10 | Setting increment for the section, m | 1,5 | 1,5 | 1,5 | 1,5 | 1,5 | 1,5 | 1,5 | 1,5 |

| 11 | Maximal distance from the face to the front edge of the slab, mm | 300 | 300 | 300 | 300 | 400 | 300 | ||

| 12 | Setting increment for the advancing ram, m, no less than | 0,63 | 0,63 | 0,63 | 0,63 | 0,63 | 0,63 | 0,63 | 0,63 |

| 13 | Dimensions of the pass in the fasteners, m, no less than: | ||||||||

| * height | 0,4 | 0,4 | 0,4 | 0,5 | 0,85 | 0,4 | |||

| * width | 0,7 | 0,7 | 0,7 | 0,7 | 0,8 | 0,7 | |||

| 14 | Type of control system | remote from the adjacent section | |||||||

| 15 | The roof tightening coefficient, no less than | 0,85-0,9 | 0,85-0,9 | 0,85-0,9 | 0,9 | 0,9 | 0,9 | 0,9 | |

| 16 | Activation pressure of the pressure relief valve of the hydrostatic resistance at nominal resistance of the section, MPa | 39(+2;-1) | 39(+2;-1) | 39(+2;-1) | 39(+2;-1) | 39(+2;-1) | 34(+2;-1) | 39(+2;-1) | 40(+2;-1) |

| 17 | Section mass, kg, no more than | 6940 | 7480 | 8180 | 8650 | 12000 | 19600 | 7300 | 422 |

| 18 | Support speed, m²/min, not less than | 4 | 4 | 4 | 4 | 4 | 4 | ||

| 19 | Removable formation power, m | 0,9-1,4 | 1,1-1,5 | 1,35-2,0 | 1,25-1,3 | 2,0-3,5 | 2,2-3,5 | 0,85-1,5 | 0,6-2,0 |

Overhaul of powered support sections

PEMRP LLC has the capability and experience in carrying out overhauls for sections of powered supports of both heavy and light versions, as well as their types and sizes, such as: 3KD90, 2KD90, 1KD90, 1KD80, DМ, KDD, 2KD90Т, 3KD90Т, 4KD90Т, Sputnik.

During the overhaul of this equipment, we perform the following types of operations:

• disassembly, washing, sandblasting;

• straightening of floors, shields, traverses, consoles;

• welding work for the restoration of hull parts;

• restoration of seats, holes and hinged joints;

• if necessary, manufacture and replacement of bases, floors, consoles, pusher

frames, traverses, slats, axles, levers and other parts;

• overhaul of the power hydraulics, if necessary, manufacture and replacement

with new cylinders, rams, replacement of rubber seals with new ones, including

polyurethane seals;

• integration of new control hydraulics and high-pressure hoses;

• tests of power hydraulics and the repaired section on specialized certified

stands.

Through the introduction of modern technology, the use of high quality materials and components, including leading European manufacturers, conscientious attitude to the work of our employees, compliance with standards and high requirements, we achieve high quality repairs, which increases the service life of the support up to 80% of the life of new equipment.