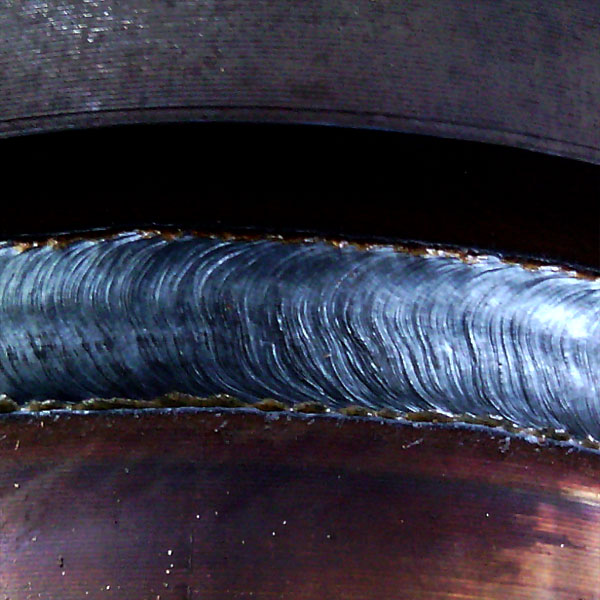

Surfacing works

Surfacing is the application of a layer of metal to the surface of the product by welding. Surfacing can be carried out both in the manufacture of new parts, and in repair and restoration work, significantly prolonging the life of parts and components, thus providing a high economic effect.

With the help of surfacing on the working surfaces of parts layers of any thickness, any chemical composition with various properties (high hardness and wear resistance), layers of anti-friction, acid-resistant, heat-resistant, cavitation-resistant, etc. can be obtained. The weight of the molten metal is usually several percent of the product weight.

When using constructions with surfaced wear-resistant layers, a significant increase in the durability of the most loaded machine parts and mechanisms is achieved.

The equipment available at our enterprise allows to realize a full cycle of restoration of details by internal or external surfacing and up to duct/ bore of necessary nominal sizes.