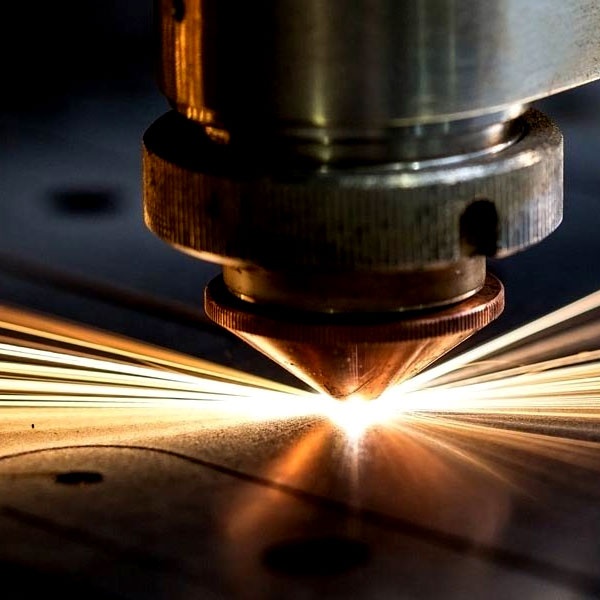

Plasma cutting

Special alloys, stainless steels, non-ferrous metals and alloys based on them, for which plasma cutting is required, are increasingly used in modern machine building.

Plasma cutting provides higher productivity compared to oxygen cutting and when cutting ferrous metals and alloys.

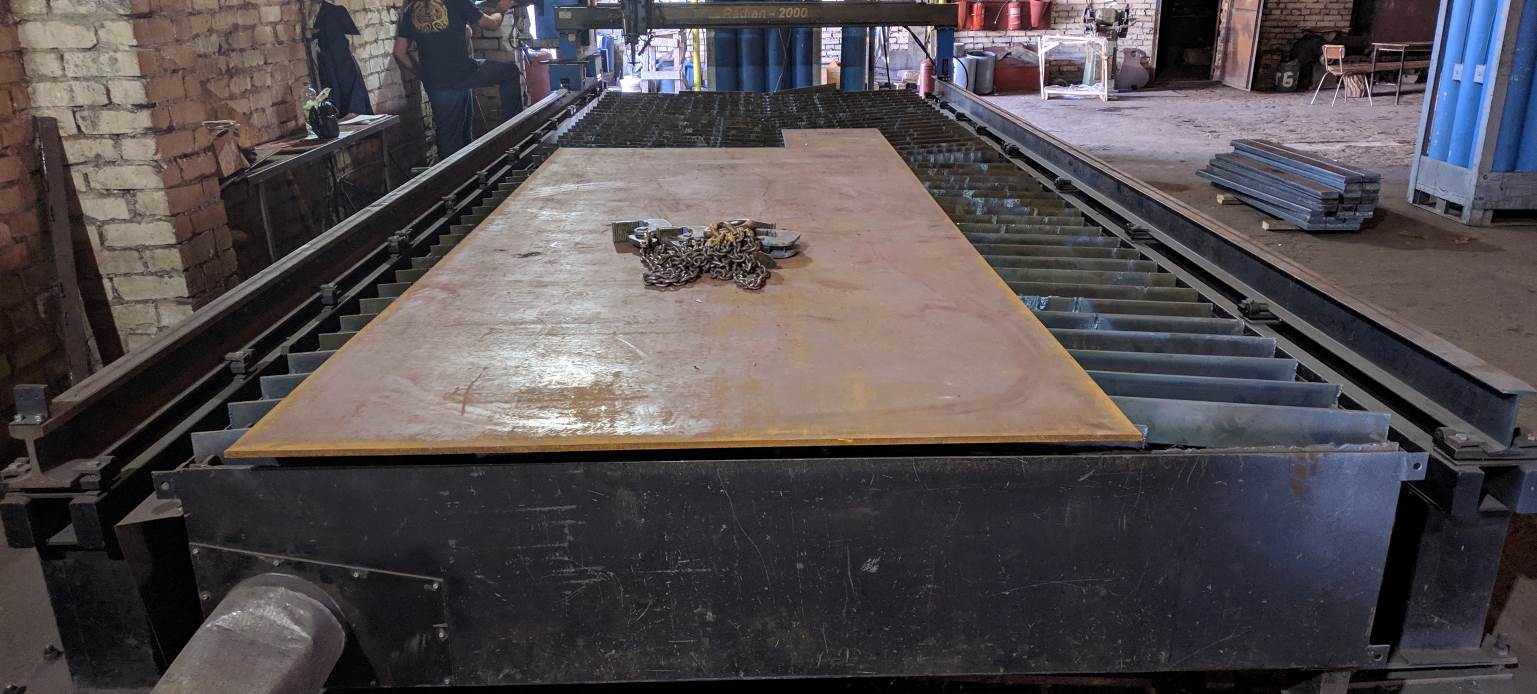

Our company offers metal cutting services with a CNC-controlled Radian®-2000 thermal cutting machine that performs shaped cutting of sheet metal with a sheet width of up to 2000 mm and length of up to 6000 mm.

Metal is cut with plasma (microplasma) cutters or oxygen cutters.

TECHNICAL SPECIFICATION

| Series: | Radian® - 2000 |

| Type of actuator: | portal |

| Way of moving the portal: | console |

| Dimensions of the processed sheet (mm), no less than: |

2050 х 6100 |

| Minimal movement speed (mm/min), no more than: |

1 |

| Precision of cut parts, cutting surface quality according to the National State Standard 14792-80 | class 1 |

| MICROPLASMA CUTTING | |

| Processed material | carbon steels, corrosion-resistant steels, aluminium alloys, copper-based alloys, titanium and its alloys |

| The thickness of the metal | is determined is determined by the passport for the selected power source. |

| OXYGEN METAL CUTTING | |

| Processed material | carbon, structural and low-alloy steels |

| Thickness of the metal | from 3mm. The upper limit is determined by the technical requirements of the Customer and can be up to 300 mm. |